At a Glance

- Babybel will replace its outer cellophane wrap with recyclable paper packaging by 2027.

- The change will affect 100% of products made in five factories and sold in 50 countries.

- The red wax coating will stay the same.

Why it matters: The move is a key step toward a 2030 goal of making all Babybel packaging recyclable or compostable at home.

—

Babybel is updating its iconic red packaging to a more sustainable format. The brand announced that the shift will replace the outer cellophane wrap with recyclable paper, a change that will roll out globally by 2027. The red wax shell, which protects the cheese, will remain unchanged.

Global Rollout Timeline

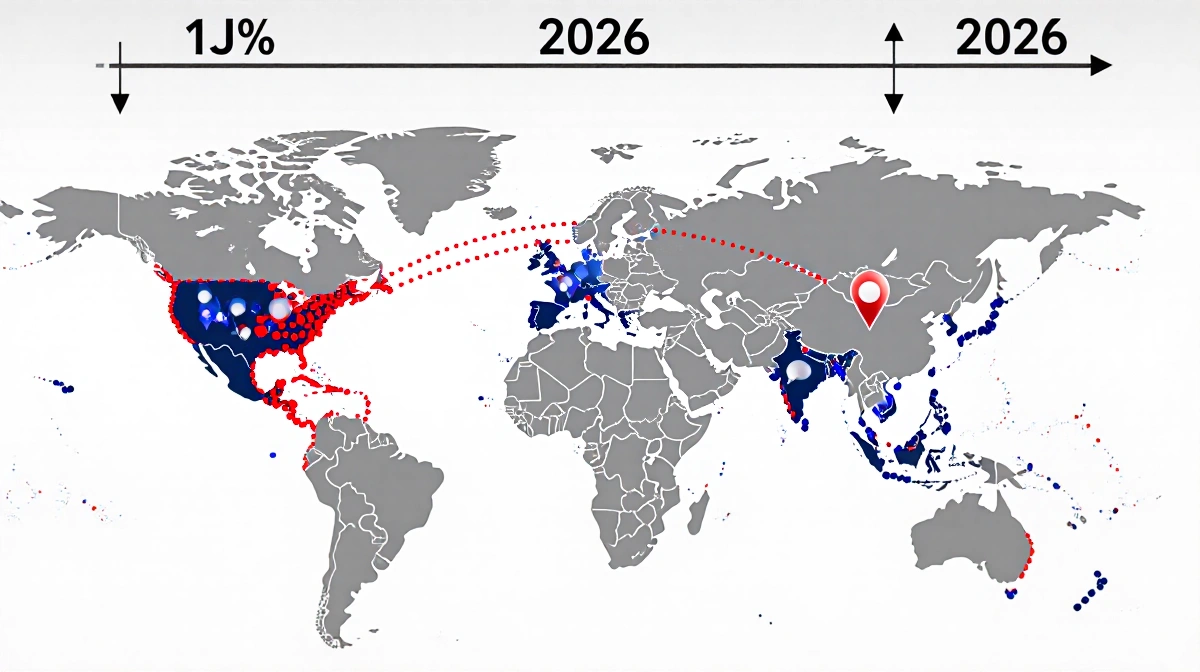

The transition will occur in stages, beginning in the United Kingdom and expanding to the United States, Canada, and Northern Europe in 2026. A full global rollout across all 50 markets is planned for 2027.

| Year | Region | Status |

|---|---|---|

| 2025 | UK | Pilot phase |

| 2026 | US, Canada, Northern Europe | Commercial rollout |

| 2027 | All 50 markets | Full adoption |

Packaging Transition Details

- The new packaging uses responsibly sourced paper.

- It has undergone extensive factory trials and real-world testing.

- Durability and food-safety standards have been met at scale.

- The paper design preserves the cheese’s original look and feel.

Béatrice de Noray, executive vice president of growth at the Bel Group, said the change reflects Babybel’s ability to evolve with societal expectations. “Babybel has been part of families’ lives for more than 70 years. Its uniqueness lies in both its universal appeal and its ability to evolve with changing uses, food cultures and societal expectations,” she added.

Technical Challenges

Delphine Chatelin, director of research, innovation and development at the Bel Group, explained that the transition is a “true technical and industrial challenge.” She noted that it is not simply about swapping one material for another; it requires rethinking the entire protection system from production to consumption. “We had to ensure product quality and safety at every step,” Chatelin said.

Impact and Sustainability Goals

With more than 2 billion portions sold worldwide each year, the shift to recyclable paper packaging is a decisive milestone in Babybel’s sustainable transformation. Linda Neu, Babybel’s global director, highlighted the global impact of this evolution. “Moving to recyclable paper packaging is a decisive milestone in Babybel’s sustainable transformation,” she said.

The rollout aligns with Bel Group’s broader goal of making all packaging recycling-ready or compostable at home by 2030. The company’s earlier move to bio-based, home-compostable cellophane in 2020 laid the groundwork for this next step.

—

The transition demonstrates how a longstanding brand can innovate while maintaining product integrity. As Babybel continues to adapt its packaging, consumers can enjoy the familiar taste and protection of their favorite cheese in a more environmentally friendly format.